Description

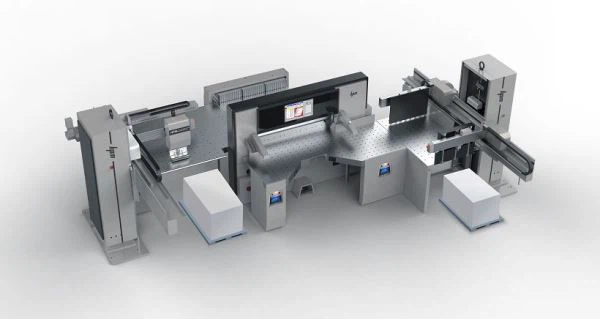

HPM Paper Cutter

– New Solutions to improve business efficiency, waste and energy consumption reduce by 18%

– The cutting efficiency of HPM machine is roughly 15% higher than other machines inthe market

SQZK S15

1.SQZK series with 15” color display and touch-screen from Japan

2. Storage: 200 programs, each program no limit with request

3. Max Backgauge Speed: 20m/min

4. Knife: Standard Knife

5. Single arm type for the knife bed

6. Language: Multi-language like English, Spanish….

7. Program cut counter

8. USB port for program updates and transfers

High Speed Paper Cutter SQZK137S15

| Model | 137S15 |

| Max.Cutting Width | 1370mm (53.9inch) |

| Max.Cutting Length | 1370mm (53.9inch) |

| Max.Cutting Height | 165mm (6.5inch) |

| Min Cutting Size (without false clam plate) | 30mm |

| Min.Cutting Size (with false clam plate) | 90mm |

| Front Table Length | 730mm |

| Max.Clamp Pressure | 45000N |

| Max.Cutting Speed | 46time/min |

| Main Motor | 4kw |

| Gross Power | 5.85kw |

| Net Weight | 4100kg |

| Gross Weight | 4500kg |

| Packing Size (L*W*H) | 2900*1750*2120mm |

Looking through the machine

German Hydraulic System, Italy Oil Pump |

Siemens PLC from Germany |

Main performance of paper cutter

The chrome-plated working platform of the program-controlled paper cutter saves the user’s maintenance time and prolongs its service life.

The paper cutter working platform is also equipped with a blowing structure to facilitate paper feeding and paper feeding.

The paper cutter is equipped with a highly reliable 8 sets of grating protection to ensure the operator’s personal safety.

The paper cutter hook-type loading structure makes the tool change work simple and easy.

The paper cutter has a high-precision, high-stiffness frame-type paper feeding mechanism and a wiring double guide rail to ensure the accuracy of paper feeding.

Paper cutter worm gear drive mechanism, hydraulic clutch, mechanical brake;

Avis

Il n’y a pas encore d’avis.