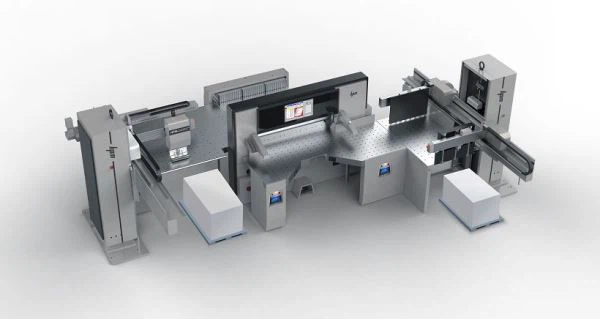

Description

HPM Paper Cutting Machine,which is supermatic and highly efficient, can cut all kinds of printed matter. Standard CIP4 cutting system and imported proportional valve make it more handy for business cared cutting and various types of paper products.

-More than 32years history for producing paper cutting machine, window patching and auxiliary equipments.

-Main drafter for the national standard of paper cutting machine, stack unloader and window patching machine, advanced unit of national committee of standardization of printing machinery

-As National High-tech Enterprises since 2009

-Passed ISO9001 Quality Management System, ISO14001 Environmental Management System and CE certification.

HPM S22

1. 22” color display and touch-screen from Japan

2. Storage: 200 programs, each program no limit with request

3. Max Backgauge Speed: 38m/min

4. Knife: HSS Knife from Japan

5. 2nd generation Proportional valve automatic adjusting the pressure、

6. Language: Multi-language

High Speed Paper Cutter HPM168S22

| Model | 168S22 |

| Max.Cutting Width | 1680mm (66.1inch) |

| Max.Cutting Length | 1680mm (66.1inch) |

| Max.Cutting Height | 165mm (6.5inch) |

| Min Cutting Size (without false clam plate) | 30mm |

| Min.Cutting Size (with false clam plate) | 90mm |

| Front Table Length | 750mm |

| Max.Clamp Pressure | 60000N |

| Max.Cutting Speed | 46time/min |

| Main Motor | 5.5kw |

| Gross Power | 8.4kw |

| Net Weight | 6200kg |

| Gross Weight | 7000kg |

| Packing Size (L*W*H) | 3600*2050*2200mm |

Configuration List

| No. | Name | Brand, specification & model | Origin of brand |

| 1 | Background LCD | 15’’Color touch Interface SHARP | Japan |

| 3 | Backgauge position motor | PANASONIC servo motor | Japan |

| 4 | Sensor | Autonics | Korea |

| 5 | Limit switch | Schneider | France |

| 6 | Guarding motor | Schneider | France |

| 7 | Air switch | Schneider | France |

| 8 | AC Contactor | Schneider | France |

| 9 | Miniature relay | Schneider | France |

| 10 | Switching power supply | Schneider | France |

| 11 | Power switch | CANSEN | China |

| 12 | Press-button | Schneider | France |

| 13 | Ball screw | High accurate | China |

| 14 | Linear guider | High accurate double linear guides | China Taiwan |

| 15 | Hydraulic Valve | Combination Valve | Italy |

| 16 | Oil Pump | Double Gear Pump | Italy |

| 17 | Bearing | NSK | Japan |

| 18 | Work Table | Slotless and plated chromium work table | China |

Looking through the machine

German Hydraulic System, Italy Oil Pump |

Siemens PLC from Germany |

Electronic Knife Lock Safety Device |

Japan Panasonic Servo Motor |

Fast, simple, safe knife changes |

Air table allows for easy paper movement |

How to make the cutter cutter more durable:

First, pay attention to whether the paper cutter has a slip phenomenon or not, and whether the cutting precision meets the required standard.

Second, pay attention to the safety index of the paper cutter and what protective measures are in place to make the operator safer.

Third, the choice of the cutting edge angle of the paper cutter is also very important. Introducing the quality and effect of cutting is reflected in the cutting blade and sharpening process.

Fourth, it is recommended to purchase products with motor components with mechanical brakes, which avoids the dangerous situation of ‘sliding knives’.

Fifth, the stability of the operation of the various parts of the paper cutter, the reliability of the overall quality and performance.

Sixth, the sensitivity and flexibility of each button of the operating platform of the paper cutter, the noise level

Avis

Il n’y a pas encore d’avis.