Description

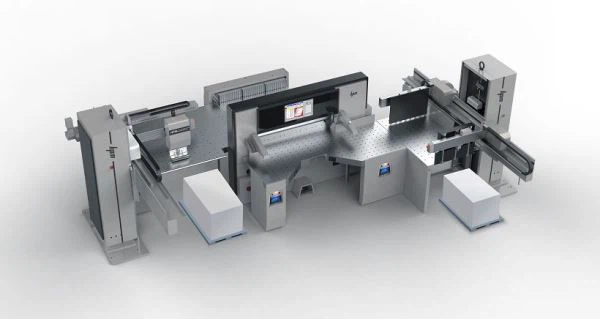

printing paper cutting machine

Traditional combined industrial printing for 10 hours.

Intelligent combined industrial printing takes only 6.5 hours.

Reduce the setting time of cutting program to zero.

– CIP4 imposition cutting system.

– it can parse files in JDP format and other various irregular imposition files.

– operation interface is simple and clear. Visual cutting program and animation guidace could be created automatically. It will make sure there is no error taken place in cutting process.

– WIFI and wireline networks are both available, it can read and parse files directly from imposition computer, A network socket is reserved for data transmission.

– The cutting file created by imposition is compatible with various intelligent device.

HPM S22

1. 22” color display and touch-screen from Japan

2. Storage: 200 programs, each program no limit with request

3. Max Backgauge Speed: 38m/min

4. Knife: HSS Knife from Japan

5. 2nd generation Proportional valve automatic adjusting the pressure、

6. Language: Multi-language

High Speed Paper Cutter SQZK137GS22

| Model | 137GS22 |

| Max.Cutting Width | 1370mm (53.9inch) |

| Max.Cutting Length | 1370mm (53.9inch) |

| Max.Cutting Height | 210mm (8.3inch) |

| Min Cutting Size (without false clam plate) | 30mm |

| Min.Cutting Size (with false clam plate) | 90mm |

| Front Table Length | 730mm |

| Max.Clamp Pressure | 60000N |

| Max.Cutting Speed | 46time/min |

| Main Motor | 5.5kw |

| Gross Power | 7.8kw |

| Net Weight | 5100kg |

| Gross Weight | 5800kg |

| Packing Size (L*W*H) | 3420*2060*2330mm |

Configuration List

| No. | Name | Brand, specification & model | Origin of brand |

| 1 | Background LCD | 15’’Color touch Interface SHARP | Japan |

| 3 | Backgauge position motor | PANASONIC servo motor | Japan |

| 4 | Sensor | Autonics | Korea |

| 5 | Limit switch | Schneider | France |

| 6 | Guarding motor | Schneider | France |

| 7 | Air switch | Schneider | France |

| 8 | AC Contactor | Schneider | France |

| 9 | Miniature relay | Schneider | France |

| 10 | Switching power supply | Schneider | France |

| 11 | Power switch | CANSEN | China |

| 12 | Press-button | Schneider | France |

| 13 | Ball screw | High accurate | China |

| 14 | Linear guider | High accurate double linear guides | China Taiwan |

| 15 | Hydraulic Valve | Combination Valve | Italy |

| 16 | Oil Pump | Double Gear Pump | Italy |

| 17 | Bearing | NSK | Japan |

| 18 | Work Table | Slotless and plated chromium work table | China |

Looking through the machine

German Hydraulic System, Italy Oil Pump |

Siemens PLC from Germany |

Electronic Knife Lock Safety Device |

Japan Panasonic Servo Motor |

Fast, simple, safe knife changes |

Air table allows for easy paper movement |

Paper machine safety operation matters needing attention

The paper cutter greatly simplifies our work, but it also carries certain risks and operates according to the regulations:

1. The paper cutter must be kept by a full-time staff. If it is not approved, non-native personnel are not allowed to operate privately.

2. To work first, wear neatly according to the production safety requirements and wipe the paper-cutting table surface cleanly. The table top is ash-free and oil-free, ensuring that the paper is white and flawless.

3. Before starting the paper cutting, the photoelectric safety device must be inspected once, and only when it is confirmed that the work is reliable, can it be put into formal production.

Paper cutter energy saving technology reduces production costs

4. The paper cutting table is not allowed to place steel rulers, hand labor, bolts, gaskets and other metal products to avoid major accidents.

5. In order to ensure the quality of the cutting paper, the blade should be changed frequently. When replacing, use a special knife holder to prevent the knife from hurting. When replacing the blade, the machine should cut off the power.

6. The replaced blade to be sharpened must be fixed and fixed by a special wood board. The edge of the plate is not allowed to be exposed to avoid falling and injuring people.

7. Every day, the paper cutting table should be cleaned, and then waxed or rust-proof.

8. In case of computer or electrical failure, unrelated personnel shall not inspect and repair the arbitrarily.

9. Keep the machine well lubricated. Check the oil level of the lubricating oil pump before going to work. Press the oil pump handle a few times by hand and grease the lubrication points once a week.

10. After the work is completed, turn off the main power of the machine before leaving.

11. It is strictly forbidden to drink and take illegal drugs to work.

Avis

Il n’y a pas encore d’avis.